The same manufacturing plant also produces 1000 units of another product, which we call product Y, using 500 labor hours. Some examples of variable manufacturing overhead costs are the cost of utilities such as electricity, water or fuel to operate machinery and supplies such as protective equipment or sales commissions. This rate is https://www.bluetextile.com/how-to-setup-quickbooks-step-by-step/ established at the beginning of a period using estimated overhead costs and activity levels, ensuring streamlined accounting and better cost control.

- The price using units of production as a basis is $47,500 while the price using labor hours as a basis is $46,250.

- A predetermined overhead rate is an estimated rate businesses use to apply manufacturing overhead costs to products or services, established before actual costs are known.

- If you’re new to managerial accounting, mastering POHR is a crucial step toward financial proficiency.

- Rather than lump overhead costs into one expense account, businesses should allocate fixed and variable overhead to departments.

- Salespeople on the road are getting the same real-time data that managers and workers are the floors are using to run production.

- Calculating the Predetermined Overhead Rate (POR) is a critical step in cost accounting, particularly in the manufacturing sector.

Overhead Rate Formula: A Comprehensive Guide

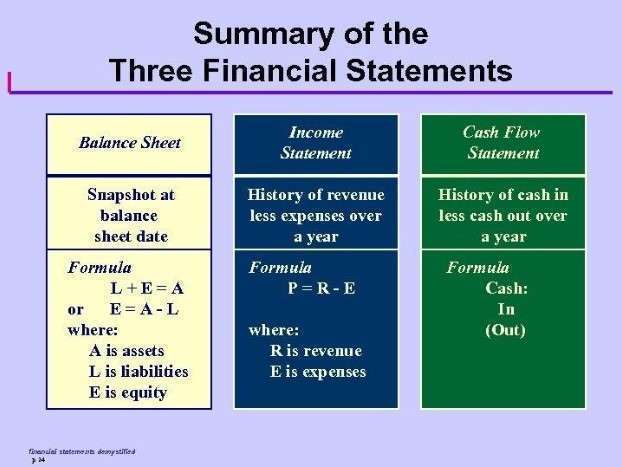

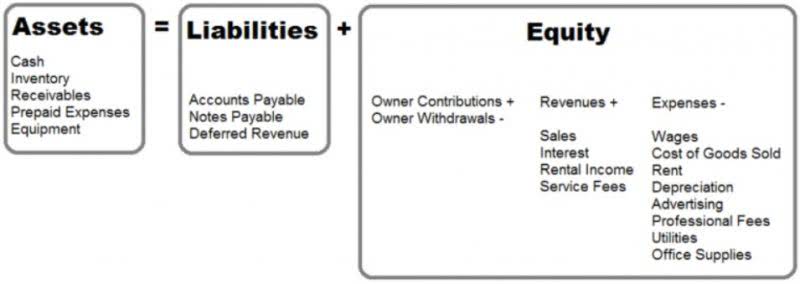

The third step is to compute the predetermined overhead rate by dividing the estimated total manufacturing overhead costs by the estimated total amount of cost driver or activity base. Common activity bases used in the calculation include direct labor costs, direct labor hours, or machine hours. As a result, the overhead costs that will be incurred in the actual production process will differ from this estimate. The activity base (also known as the allocation base or activity driver) in the formula for predetermined overhead rate is often direct labor costs, direct labor hours, or machine hours. That is, a number of possible allocation bases such as direct labor hours, direct labor dollars, or machine hours can be used for the denominator of the predetermined overhead rate equation. The predetermined overhead rate is calculated by dividing the estimated manufacturing overhead by the estimated activity base (direct labor hours, direct labor dollars, or machine hours).

Allow Business to Use Consistent Costing Standards

Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year. The manufacturing overhead costs are applied to the product based on the actual number of activity base units used during the accounting period. Suppose GX company uses direct labor hours to assign manufacturing overhead cost to job orders.

- These physical costs are calculated either by the declining balance method or a straight-line method.

- So, a more precise practice of overhead absorption has been developed that requires different and relevant bases of apportionment.

- Calculating a predetermined overhead rate is one of the first tasks management will take on because it provides a formula to estimate the production costs of a product in advance.

- The management concern about how to find a predetermined overhead rate for costing.

- Without it, companies would face delays in understanding product costs, hindering efficient operations.

- Knowing how much money you need to set aside for manufacturing overhead will help you create a more accurate budget.

Advantages of predetermined overhead rate formula

- If an actual rate is computed monthly or quarterly, seasonal factors in overhead costs or in the activity base can produce fluctuations in the overhead rate.

- A predetermined overhead rate is defined as the ratio of manufacturing overhead costs to the total units of allocation.

- This means that businesses can use the predetermined overhead rate to constantly evaluate its operations without having to wait for actual results to come in.

- You also need to closely monitor your production schedule so you can make adjustments as needed.

In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate. For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process. This is related to an activity rate which is a similar calculation used in activity-based costing. A pre-determined overhead rate is normally the term when using a single, plant-wide base to calculate and apply overhead. Overhead is then applied by multiplying the pre-determined overhead rate by the actual driver units.

Predetermined Overhead Rate (Definition, Example, Formula, and Calculation)

Once costs are broken down, small businesses can assess if any categories Accounts Receivable Outsourcing are excessive. Renegotiating contracts with vendors may yield savings on supplies or services. Chartered accountant Michael Brown is the founder and CEO of Double Entry Bookkeeping.

We also use the same rate to calculate the inventory balance at the end of accounitng period. However, the variance between actual overhead and estimated will be reconciled and adjust to the financial statement. This $4 per hour overhead rate would then be applied to the number of direct labor hours for each job to allocate overhead costs. Suppose that X limited produces a product X and uses labor hours to assign the manufacturing overhead cost.

Breaking Down Overhead Costs: Fixed and Variable

The cost of goods sold consists of direct materials of $3.50 per unit, direct predetermined factory overhead rate labor of $10 per unit, and manufacturing overhead of $5.00 per unit. With 150,000 units, the direct material cost is $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000. The predetermined overhead rate computed above is known as single or plant-wide overhead rate which is mostly used by small companies.

It is calculated before the period begins and is used to assign overhead costs to production using an allocation rate per unit of activity, such as direct labor hours. As you’ve learned, understanding the cost needed to manufacture a product is critical to making many management decisions (Figure 6.2). Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.